Natural honeycomb structures occur in many different environments, from beehives to honeycomb weathering in rocks. Based on these, man-made honeycomb structures have been built with similar geometry to allow the reduction of the quantity of material used, and thereby realizing minimal weight and material cost.

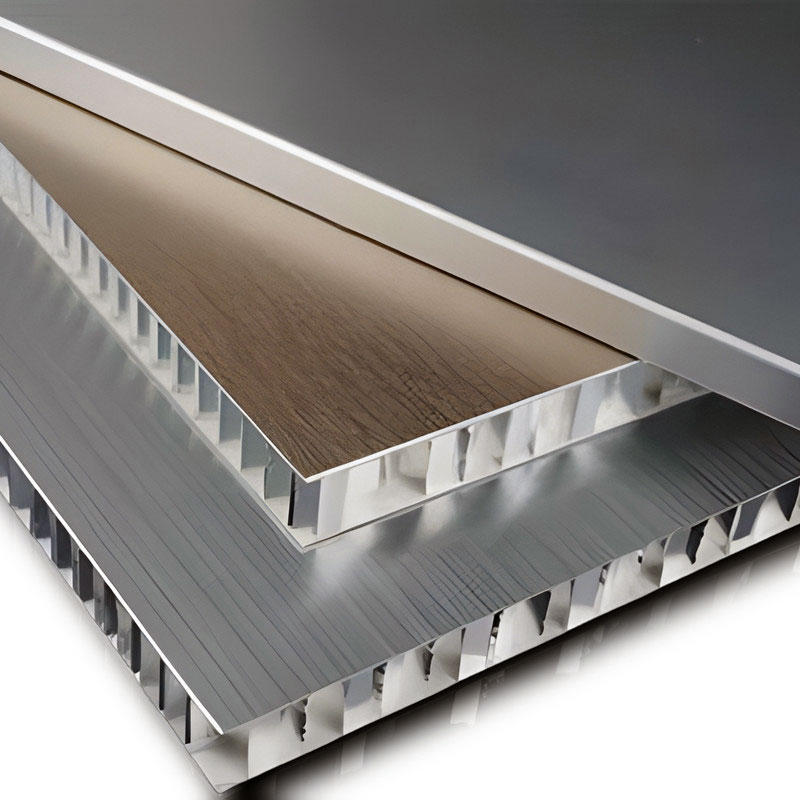

Man-made honeycomb structures have an array of hollow cells formed between thin vertical walls, so that the material has minimal density, strength in tension and high out-of-plane compression properties. Aluminum Honeycomb Panels Aerospace

Honeycomb structures are manufactured using three conventional methods, namely, expansion, corrugation and molding, which can be traced back to the 1900s.

Today, the manufacture of honeycomb cores involves the use of the expansion and corrugation processes where composite materials such as fibreglass, aluminium, and carbon fiber reinforced plastic are used. To manufacture thermoplastic honeycomb cores, the raw material used is polypropylene and the method used is extrusion.

A more recent cost efficient method for the manufacture of thermoplastic honeycomb structures enables continuous in-line production and direct lamination of skin. Similarly, continuous in-line production of metal honeycomb can also be performed from metal rolls by cutting and bending.

Apart from metal honeycomb composite structures, there are also paperboard honeycomb materials that are being manufactured for use in paper pallets and package blocking, cushioning, and bracing.

The following is a list of companies manufacturing a variety of honeycomb composite materials with a brief introduction to each:

The key benefits of using honeycomb composites are given below:

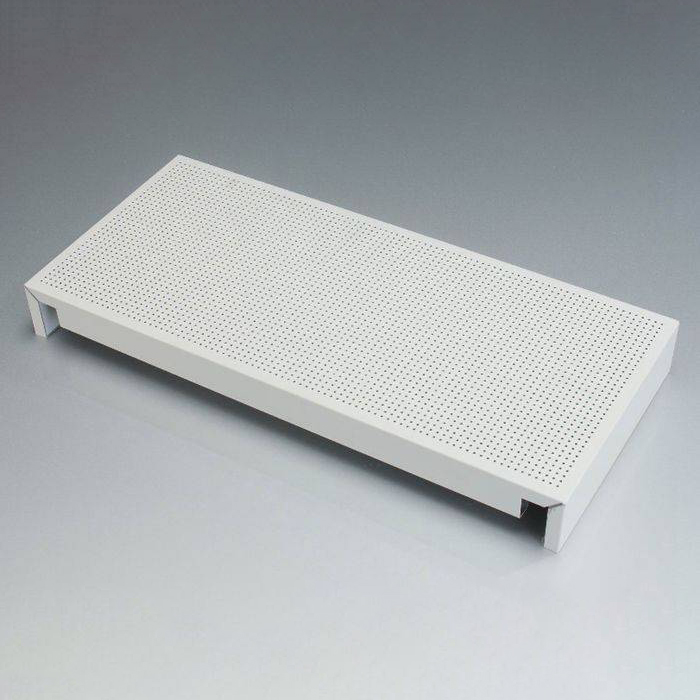

Honeycomb materials can be used in a huge number of applications. Some of the common applications are as follows:

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Gary graduated from the University of Manchester with a first-class honours degree in Geochemistry and a Masters in Earth Sciences. After working in the Australian mining industry, Gary decided to hang up his geology boots and turn his hand to writing. When he isn't developing topical and informative content, Gary can usually be found playing his beloved guitar, or watching Aston Villa FC snatch defeat from the jaws of victory.

Please use one of the following formats to cite this article in your essay, paper or report:

3A Composites. (2019, October 02). Innovations in Honeycomb Composites. AZoM. Retrieved on January 29, 2024 from https://www.azom.com/article.aspx?ArticleID=8379.

3A Composites."Innovations in Honeycomb Composites".AZoM.29 January 2024.

3A Composites. "Innovations in Honeycomb Composites". AZoM. https://www.azom.com/article.aspx?ArticleID=8379. (accessed January 29, 2024).

3A Composites. 2019. Innovations in Honeycomb Composites. AZoM, viewed 29 January 2024, https://www.azom.com/article.aspx?ArticleID=8379.

Do you have a review, update or anything you would like to add to this article?

In this interview, AZoMaterials speaks with Knauer about project management capabilities in OEM, customization abilities, as well as what makes Knauer OEM solutions unique.

Andrea Steck, Martius Cobo, Bruno Chencarek

In this interview, join Bruker as they describe how to improve battery production and performance, through the entire value chain, with the help of NMR.

In this interview, Sara Speak, the Industrial and Environmental Product Application Specialist at Veolia Water Technologies & Solutions, talks to AZoMaterials about the current challenges the food and beverage industry (F7b) faces in water management.

The Wafer XRD 300 is a integratable wafer Ooientation solution

This product profile describes the features and applications of the FOX 200 HT for measuring thermal conductivity.

This product profile describes the features and applications of the PlasmaPro ASP by Oxford Instruments Plasma Technology.

The global semiconductor market has entered an exciting period. Demand for chip technology is both driving the industry as well as hindering it, with current chip shortages predicted to last for some time. Current trends will likely shape the future of the industry, which is set to continue to show

The primary distinction between graphene-based batteries and solid-state batteries lies in the composition of either electrode. Although the cathode is commonly changed, carbon allotropes can also be employed in fabricating anodes.

In recent years, the IoT is rapidly being introduced into almost all sectors, but it has particular importance in the EV industry.

AZoM.com - An AZoNetwork Site

Honeycomb Structural Panels Supplier Owned and operated by AZoNetwork, © 2000-2024